Heavy Duty Smart Linear Position Sensing Cylinder CYLNUC®

Description

CYLNUC is NSD smart and heavy duty cylinder linear position sensing cylinder that indicates the amount of linear travel and rod extension throughout the range of sensing stroke.

Hydraulic type SCHH / Pneumatic type SCAH

Ex.

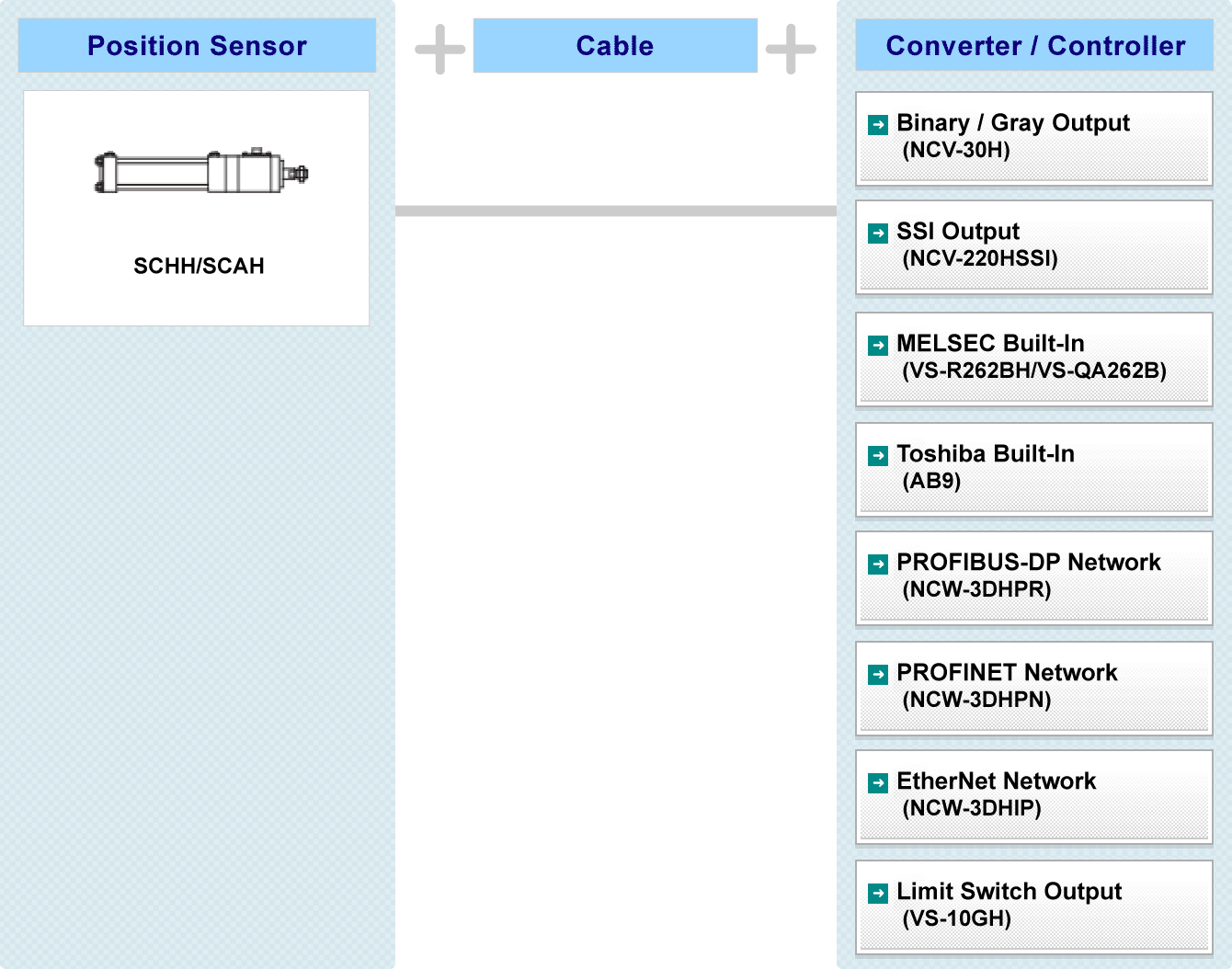

System Configuration

Specification

Cylinder

| Item | Specification | |||||

|---|---|---|---|---|---|---|

| Bore size (mm) | φ40 | φ50 | φ63 | φ80 | φ100 | |

| Rod dia. (mm) | φ18 | φ20 | φ20.4 | φ28 | φ36 | |

| Stroke(mm) | Without bellows | 50〜1000 | 50〜1400 | 50〜1600 | 50〜1800 | |

| With bellows | 50〜1400 | 50〜1500 | ||||

| Operating pressure range(MPa) | 0.2〜5.0 | |||||

| Proof test pressure(MPa) | 7.5 | |||||

| Operating fluid | Mineral oil, water-glycol | |||||

| Cylinder speed range(mm/s) | 3〜300 | |||||

| Ambient operating temperature(℃) | 5〜120 | |||||

Applicable sensor

| Item | Specification |

|---|---|

| Absolute detection range(mm) | 12.8 |

| Resolution(μm) | 1.5625 |

| Repeatability(μm) | 10 mim. [Without load] |

| Linearity error(mm) | 0.15 + L/1000 Max. L:stroke |

| Protection rating | IP67(Conforms to JEM 1030 standard) |

| Vibration resistance | 2.0×102 m/s2 {20G} 200Hz up /down 4h, forward/back 2h, conforms to JIS D1601 standard |

| Shock resistance | 4.9×103 m/s2 {500G} 0.5ms up/down/forward/back 3 times each, conforms to JIS C5026 standard |

Theoretical cylinder thrust values at various operating pressures

| Bore size (mm) |

Cross-sec. area of cylinder (mm2) |

Rod dia. (mm) |

Cross-sec. area of piston rod (mm2) |

Area of piston's rod face (mm2) |

Cylinder thrust (N) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1.0MPa | 2.0MPa | 3.0MPa | 3.5MPa | 5.0MPa | ||||||

| φ40 | 1256 | φ18 | 254 | Push | 1256 | 1256 | 2513 | 3769 | 4398 | 6283 |

| Pull | 1002 | 1002 | 2004 | 3006 | 3507 | 5010 | ||||

| φ50 | 1963 | φ20 | 314 | Push | 1963 | 1963 | 3926 | 5890 | 6872 | 9817 |

| Pull | 1649 | 1649 | 3298 | 4948 | 5772 | 8246 | ||||

| φ63 | 3117 | φ22.4 | 394 | Push | 3117 | 3117 | 6234 | 9351 | 10910 | 15586 |

| Pull | 2723 | 2723 | 5446 | 8169 | 9531 | 13615 | ||||

| φ80 | 5026 | φ28 | 615 | Push | 5026 | 5026 | 10053 | 15079 | 17592 | 25132 |

| Pull | 4410 | 4410 | 8821 | 13232 | 15437 | 22053 | ||||

| φ100 | 7853 | φ36 | 1017 | Push | 7853 | 7853 | 15707 | 23561 | 27488 | 39269 |

| Pull | 6836 | 6836 | 13672 | 20508 | 23926 | 34180 | ||||

Mass

| Bore size (mm) |

Basic mass (ZERO stroke) (kg) |

Stroke mass per 10 mm (kg) |

Additional mass depending on mounting format (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OO | LB | FA | FB | CA | CB | TA | TC | |||

| φ40 | 3.2 | 0.09 | 0 | 0.51 | 0.31 | 0.31 | 0.43 | 0.50 | 0.27 | 0.42 |

| φ50 | 5.0 | 0.08 | 0 | 0.92 | 0.45 | 0.45 | 0.62 | 0.89 | 0.41 | 0.73 |

| φ63 | 5.5 | 0.10 | 0 | 1.24 | 0.62 | 0.62 | 0.96 | 1.25 | 0.50 | 0.77 |

| φ80 | 8.8 | 0.19 | 0 | 2.13 | 1.52 | 1.52 | 1.57 | 2.25 | 1.76 | 1.51 |

| φ100 | 12.4 | 0.24 | 0 | 3.44 | 2.51 | 2.51 | 2.44 | 3.36 | 2.90 | 2.69 |

Dimensions

Pneumatic type CSAH

Ex.

| Item | Code | Description | ||

|---|---|---|---|---|

| Bore size | 20 | Φ20 | Units : mm | |

| 40 | Φ40 | |||

| Stroke | 50 ~ 500 | Φ20 | 50 ~ 500 : 50 mm units 600 ~ 700 : 100 mm units |

Units : mm |

| 50 ~ 700 | Φ40 | |||

| Mounting style | [FA]Flange on rod end side |

|||

[LS]Foot on rod end side /parallel to axis  |

||||

[TB]Trunnion on head end side |

||||

[FB]Flange on head end side |

||||

[LB]Foot both ends /parallel to axis  |

||||

| Max. operating pressure | 7 | 0.7 MPa(7kgf/cm2) | ||

| 0 | Piston with hole | |||

| Connector | B | With connector(NJW-2012-PM) | ||

| R | Crimp-type terminal(R1.25-4) | |||

| Cable length | 2.0 | 2 m | ||

Option |

A1 | Lock nut (accessory) | ||

| A2 | Clevis / single | |||

| A3 | Clevis / double (supplied with a Pivot pin A4) | |||

| A4 | Pivot pin (for Clevis) | |||

| C5 | Bellows | |||

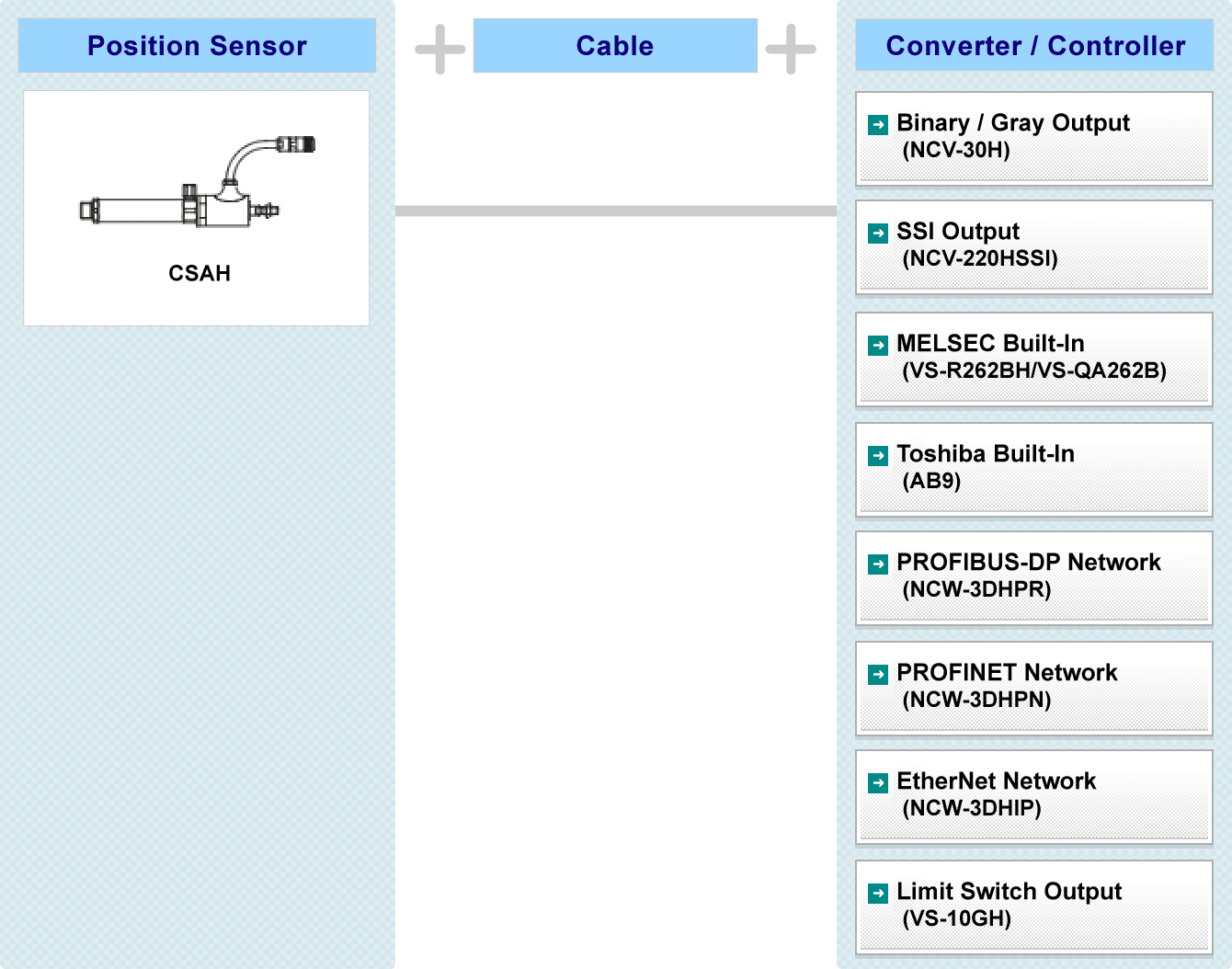

System Configuration

Specification

Cylinder

| Item | Specification | ||

|---|---|---|---|

| Bore size (mm) | φ20 | φ40 | |

| Rod dia. (mm) | φ10 | φ14 | |

| Stroke(mm) | Without bellows | 50〜500 | 50〜700 |

| With bellows | |||

| Operating pressure range(MPa) | 0.1〜0.7 | ||

| Proof test pressure(MPa) | 1.05 | ||

| Operating fluid | Compressed air | ||

| Cylinder speed range(mm/s) | 50〜500 | ||

| Ambient operating temperature(℃) | 5〜120 | ||

Applicable sensor

| Item | Specification |

|---|---|

| Absolute detection range(mm) | 12.8 |

| Resolution(μm) | 1.5625 |

| Repeatability(μm) | 10 mim. [Without load] |

| Linearity error(mm) | 0.25 + L/2000 Max. L:stroke |

| Protection rating | IP67(Conforms to JEM 1030 standard) |

| Vibration resistance | 2.0×102 m/s2 {20G} 200Hz up /down 4h, forward/back 2h, conforms to JIS D1601 standard |

| Shock resistance | 4.9×103 m/s2 {500G} 0.5ms up/down/forward/back 3 times each, conforms to JIS C5026 standard |

Theoretical cylinder thrust values at various operating pressures

| Bore size (mm) |

Cross-sec. area of cylinder (mm2) |

Rod dia. (mm) |

Cross-sec. area of piston rod (mm2) |

Area of piston's rod face (mm2) |

Cylinder thrust (N) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2MPa | 0.3MPa | 0.4MPa | 0.5MPa | 0.6MPa | 0.7MPa | ||||||

| φ20 | 314 | φ10 | 78 | Push | 314 | 62 | 94 | 125 | 157 | 188 | 219 |

| Pull | 235 | 47 | 70 | 94 | 117 | 141 | 164 | ||||

| φ40 | 1256 | φ14 | 153 | Push | 1256 | 251 | 376 | 502 | 628 | 753 | 879 |

| Pull | 1102 | 220 | 330 | 441 | 551 | 661 | 771 | ||||

Mass

| Bore size (mm) |

Basic mass (ZERO stroke) (kg) |

Stroke mass per 10 mm (kg) |

Additional mass depending on mounting format (kg) | ||||

|---|---|---|---|---|---|---|---|

| FA | FB | LB | LS | TB | |||

| φ20 | 1.2 | 0.01 | 0.06 | 0.06 | 0.15 | 0.08 | 0.10 |

| φ40 | 1.5 | 0.02 | 0.15 | 0.15 | 0.26 | 0.13 | 0.20 |

Dimensions

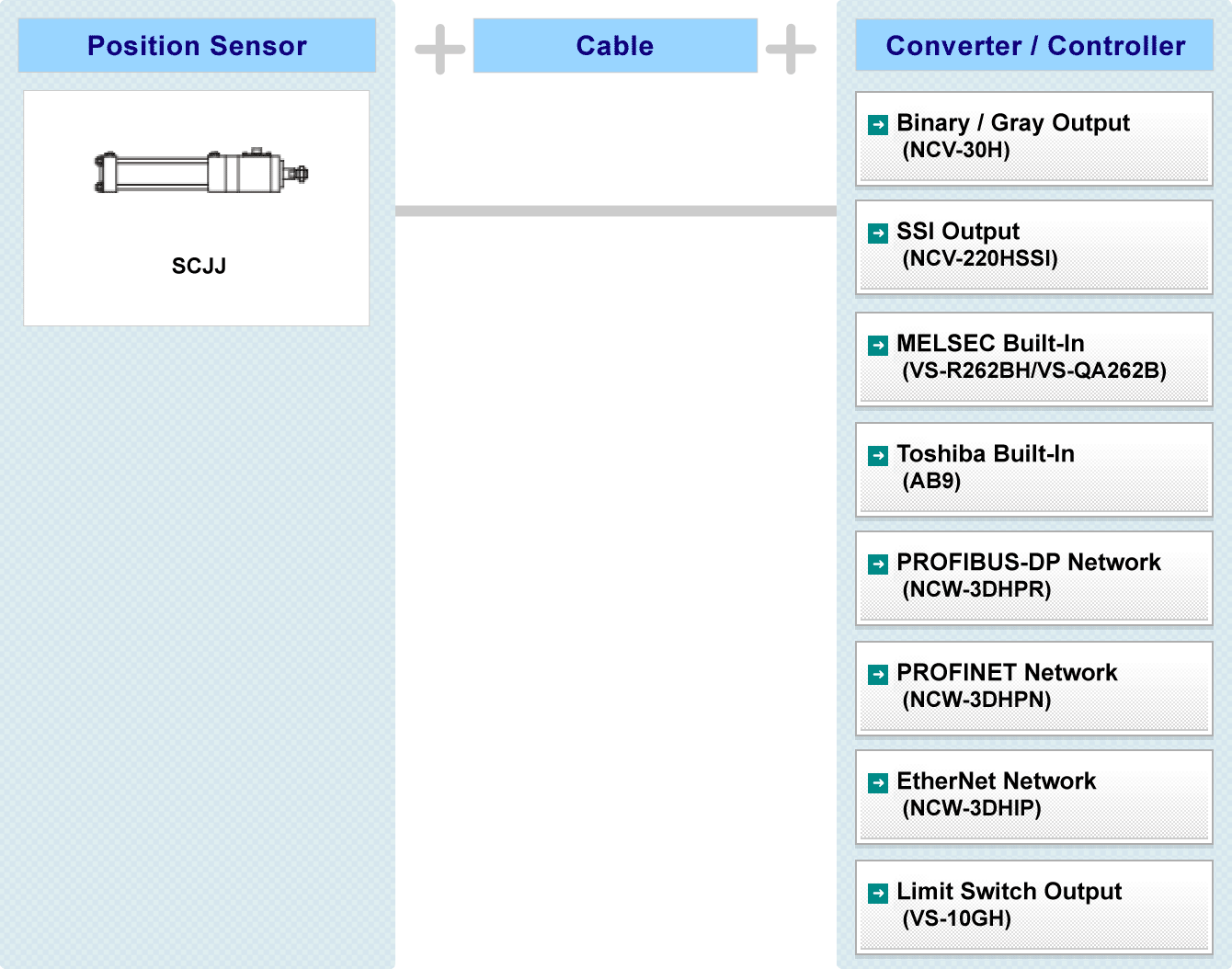

Hydraulic type SCJJ

Ex.

| Item | Code | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Operating fluid | F | Specify only if phosphate ester is required. | ||||||||||||

| Bore size (mm) | 40~160 | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 160 | |||||

| Rod dia. (mm) | B | 22 | 28 | 36 | 45 | 56 | 70 | 80 | 90 | |||||

| Stroke(mm) | With bellows: 50~300 Without bellows: 50~400 |

Bore size:40 | 50~500:50 units 600~1000:100 units 1200~1400:200 units |

|||||||||||

| 50~1200 | Bore size:50 | |||||||||||||

| 50~1400 | Bore size: 63, 80, 100,125,140,160 |

|||||||||||||

| Mounting style | [LA] | Foot/Side Lugs |

||||||||||||

| [LB] | Foot both ends /parallel to axis |

|||||||||||||

| [FD] | Flange on head end side |

|||||||||||||

| [FY] | Flange on rod end side |

|||||||||||||

| [CA] | Clevis / single |

|||||||||||||

| [CB] | Clevis / double |

|||||||||||||

| [TA] | Trunnion on Rod End Side |

|||||||||||||

| [TC] | Intermediate Fixed Trunnion |

|||||||||||||

| Maximum operating pressure | 70 | 7 MPa(70kgf/cm2) | ||||||||||||

| 140 | 14 MPa(140kgf/cm2) | |||||||||||||

| Cushion | B | Both ends of cylinder | ||||||||||||

| R | Pull | |||||||||||||

| H | Push | |||||||||||||

| N | None | |||||||||||||

| Cushion valve location *1 | A |  |

||||||||||||

| B | ||||||||||||||

| C | ||||||||||||||

| D | ||||||||||||||

| N | None | |||||||||||||

| Option | E | Long rod end | ||||||||||||

| F | Bellows, nylon tarpaulin 80℃ max. | |||||||||||||

| G | Bellows, neoprene 130℃ max. | |||||||||||||

| H | Bellows, silicone glass 250℃ max. | |||||||||||||

| (E) K *2 | Lock nut | |||||||||||||

| L | Clevis / single | |||||||||||||

| M | Clevis / double | |||||||||||||

| Connector | D | Connector (NJW-2012-RM) + no cable | ||||||||||||

| B | Connector (NJW-2012-PM) + robotic cable | |||||||||||||

| Z | No connector + robotic cable | |||||||||||||

| BH | Connector (NJW-2012-PM) + heat-resistant cable | |||||||||||||

| ZH | No connector + heat-resistant cable | |||||||||||||

| Cable length | 2 | 2m | ||||||||||||

| 5 | 5m | |||||||||||||

| 10 | 10m | |||||||||||||

| Port location *1 Air-breede location Cable location *3 Drain port location *3 |

A |  |

||||||||||||

| B | ||||||||||||||

| C | ||||||||||||||

| D | ||||||||||||||

*1: The port and the cushion valvecannot be mounted facing in the same location.

*2: If a lock nut (K) is to be mounted at the rod end, the "long rod end style" item (E) must be selected.

*3: The cable and the drain port cannot be mounted facing in the same location.

System Configuration

Specification

Cylinder

| Item | Specification | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bore size (mm) | φ40 | φ50 | φ63 | φ80 | φ100 | φ125 | φ140 | φ160 | |

| Rod dia. (mm) | φ22 | φ28 | φ36 | φ45 | φ56 | φ70 | φ80 | φ90 | |

| Maximum stroke length(mm) | Without bellows | 400 | 1200 | 1400 | |||||

| With bellows | 300 | ||||||||

| Maximum operating pressure(MPa) | 14 | ||||||||

| Proof test pressure(MPa) | 21 | ||||||||

| Operating fluid | Mineral oil, water-glycol, polyol ester, phosphate ester, water-in-oil emulsion |

||||||||

| Cylinder speed range(mm/s) | 10〜400 | 10〜300 | 10〜200 | ||||||

| Ambient operating temperature(℃) | 5〜80 | ||||||||

Applicable sensor

| Item | Specification |

|---|---|

| Absolute detection range(mm) | 12.8 |

| Resolution(μm) | 1.5625 |

| Repeatability(μm) | 10 mim. [Without load] |

| Linearity error(mm) | 0.15 + L/5000 Max. L:stroke |

| Temperature drift | t {0.0016 + ( L × 1.17 × 10-5) } t:Temperature variation(℃) L:stroke |

| Protection rating | IP67(Conforms to JEM 1030 standard) |

| Vibration resistance | 2.0×102 m/s2 {20G} 200Hz up /down 4h, forward/back 2h, conforms to JIS D1601 standard |

| Shock resistance | 4.9×103 m/s2 {500G} 0.5ms up/down/forward/back 3 times each, conforms to JIS C5026 standard |

Theoretical cylinder thrust values at various operating pressures

| Bore size (mm) |

Cross-sec. area of cylinder (mm2) |

Rod dia. (mm) |

Cross-sec. area of piston rod (mm2) |

Area of piston's rod face (mm2) |

Cylinder thrust (kN) | ||

|---|---|---|---|---|---|---|---|

| 7MPa | 14MPa | ||||||

| φ40 | 1256 | φ22 | 380 | Push | 1256 | 8.79 | 17.59 |

| Pull | 876 | 6.13 | 12.27 | ||||

| φ50 | 1963 | φ28 | 615 | Push | 1963 | 13.74 | 27.48 | Pull | 1347 | 9.43 | 18.86 |

| φ63 | 3117 | φ36 | 1017 | Push | 3117 | 21.82 | 43.64 |

| Pull | 2099 | 14.69 | 29.39 | ||||

| φ80 | 5026 | φ45 | 1590 | Push | 5026 | 35.18 | 70.37 |

| Pull | 3436 | 24.05 | 48.10 | ||||

| φ100 | 7853 | φ56 | 2463 | Push | 7853 | 54.97 | 109.95 |

| Pull | 5390 | 37.73 | 75.47 | ||||

| φ125 | 12271 | φ70 | 3848 | Push | 12271 | 85.90 | 171.80 |

| Pull | 8423 | 58.96 | 117.92 | ||||

| φ140 | 15393 | φ80 | 5026 | Push | 15393 | 107.75 | 215.51 |

| Pull | 10367 | 72.57 | 145.14 | ||||

| φ160 | 20106 | φ90 | 6361 | Push | 20106 | 140.74 | 281.48 |

| Pull | 13744 | 96.21 | 192.42 | ||||

Mass

| Bore size (mm) |

Rod dia. (mm) |

Stroke mass per 100 mm (kg) |

Additional mass depending on mounting format (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LA | LB | FY | FD | CA | CB | TA | TC | |||

| φ40 | 22 | 0.9 | 7.8 | 7.9 | 7.81 | 8.4 | 8.03 | 8.1 | 7.5 | 8.0 |

| φ50 | 28 | 1.3 | 13.1 | 13.1 | 13.3 | 14.3 | 13.3 | 13.5 | 12.4 | 13.3 |

| φ63 | 36 | 1.9 | 18.5 | 19.2 | 18.9 | 20.6 | 19.8 | 20.5 | 18.0 | 19.4 |

| φ80 | 45 | 2.9 | 26.8 | 28.1 | 28.0 | 30.6 | 28.8 | 29.7 | 26.4 | 28.2 |

| φ100 | 56 | 4.4 | 44.4 | 46.5 | 46.6 | 50.7 | 48.8 | 50.3 | 44.0 | 47.9 |

| φ125 | 70 | 7.8 | 76.1 | 83.1 | 79.7 | 86.6 | 84.0 | 87.0 | 74.6 | 81.1 |

| φ140 | 80 | 10.4 | 99.1 | 109.1 | 104.0 | 122.6 | 111.2 | 117.3 | 98.0 | 106.8 |

| φ160 | 90 | 12.5 | 136.9 | 149.5 | 143.3 | 158.5 | 155.2 | 164.1 | 135.0 | 149.0 |

Dimensions

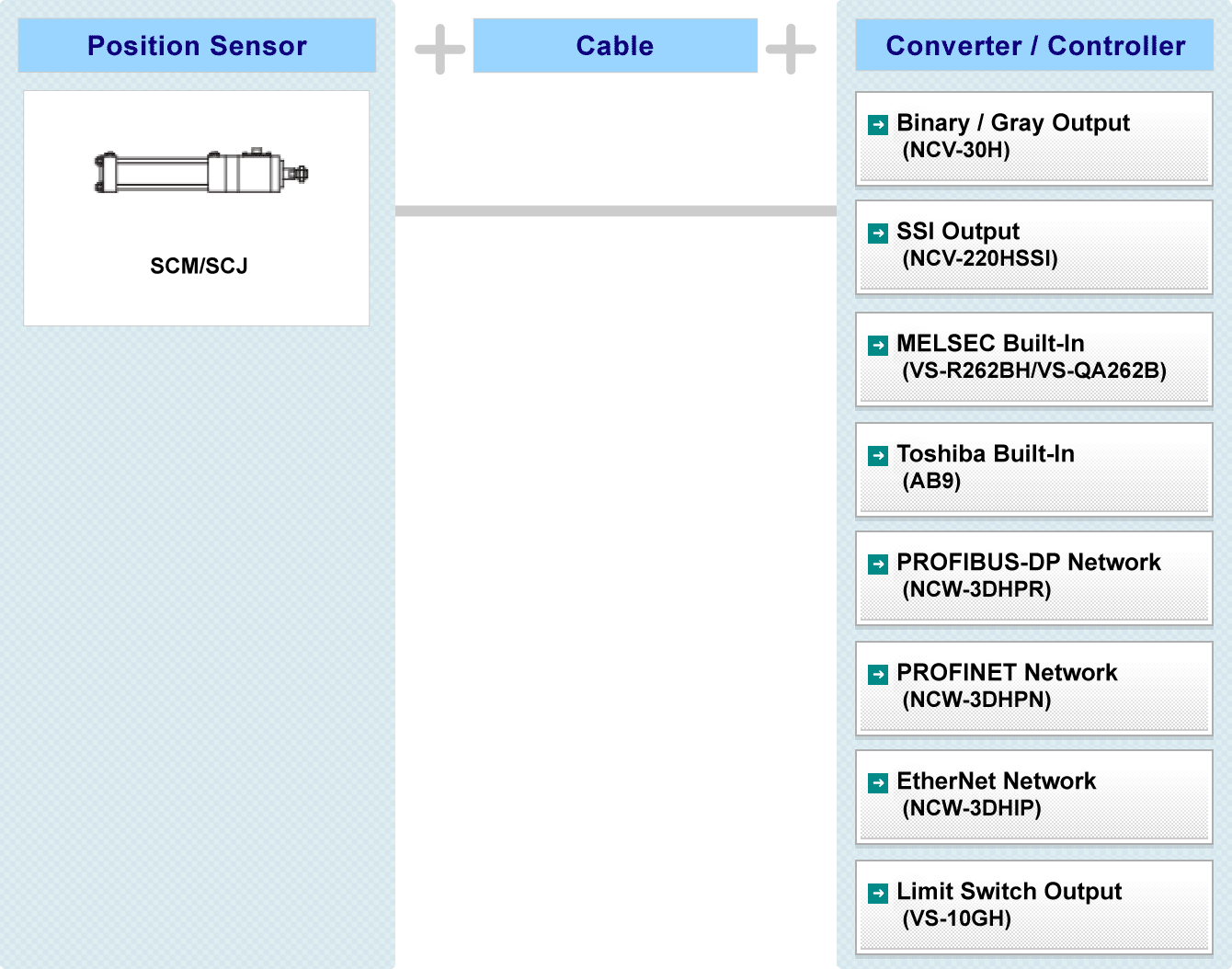

Hydraulic MILL type SCM

Hydraulic JIS type SCJ

Ex.

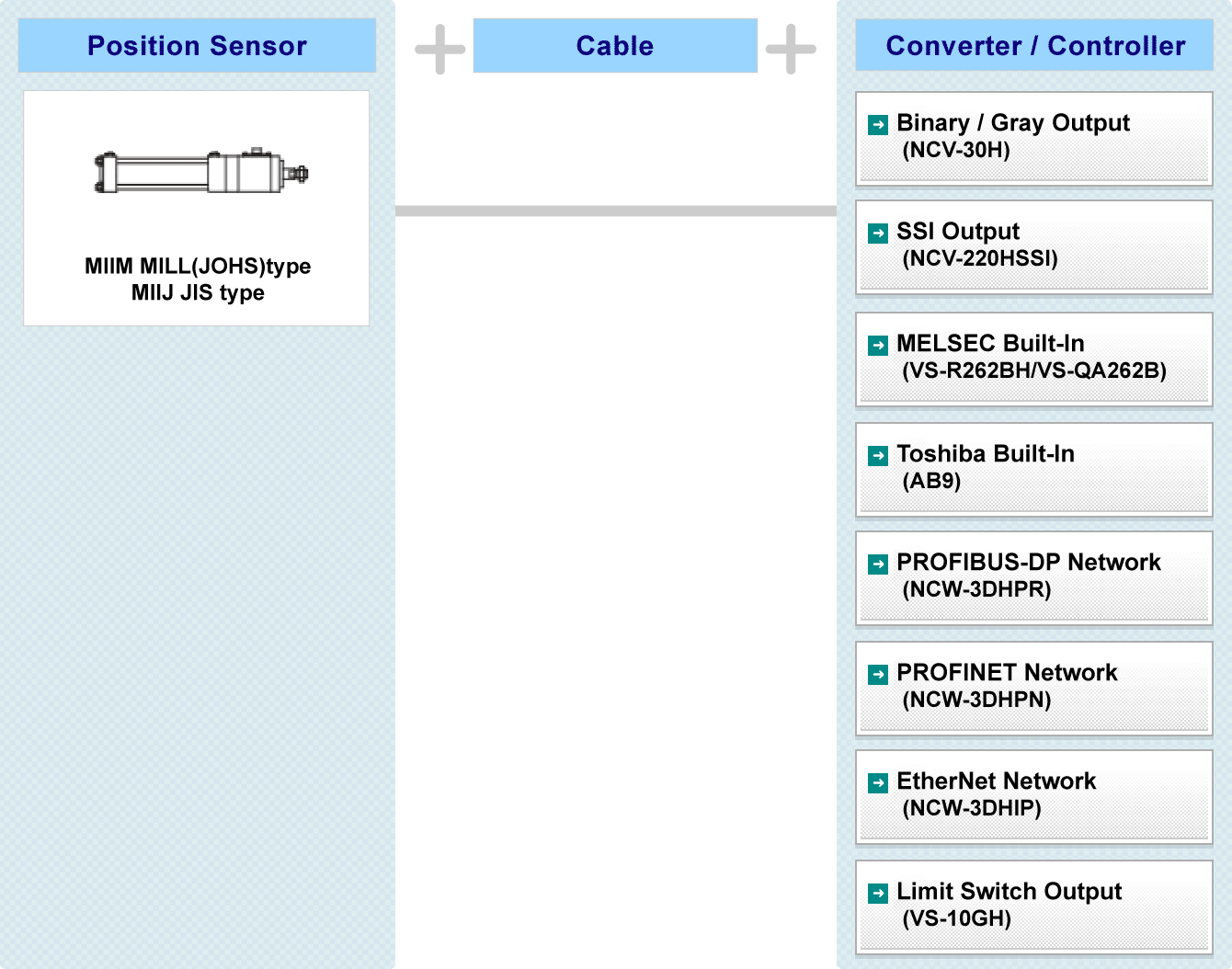

System Configuration

Specification

Cylinder

| Item | Specification | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore size (mm) | φ40 | φ50 | φ63 | φ80 | φ100 | φ125 | φ140 | φ160 | φ180 | φ200 | φ220 | φ250 | φ320 |

| Rod dia. (mm) | φ22.4 φ28 |

φ22.4 φ28 φ36 |

φ28 φ36 φ45 |

φ36 φ45 φ56 |

φ45 φ56 φ70 |

φ56 φ70 φ90 |

φ63 φ80 φ100 |

φ70 φ90 φ110 |

φ80 φ100 φ125 |

φ90 φ110 φ140 |

φ100 φ125 φ160 |

φ110 φ140 φ180 |

φ160 φ180 |

| Maximum stroke length(mm) | 1200 | 1400 | 1400 | ||||||||||

| Maximum operating pressure(MPa) | SCM:25 SCJ:21 | ||||||||||||

| Proof test pressure(MPa) | SCM:37.5 SCJ:31.5 | ||||||||||||

| Operating fluid | Mineral oil, water-glycol, polyol ester, phosphate ester, water-in-oil emulsion | ||||||||||||

| Cylinder speed range(mm/s) | 5〜500 | ||||||||||||

| Ambient operating temperature(℃) | 5〜120 | ||||||||||||

Applicable sensor

| Item | Specification |

|---|---|

| Absolute detection range(mm) | 12.8 |

| Resolution(μm) | 1.5625 |

| Repeatability(μm) | 10 mim. [Without load] |

| Linearity error(mm) | 0.15 + L/5000 Max. L:stroke |

| Protection rating | IP67(Conforms to JEM 1030 standard) |

| Vibration resistance | 2.0×102 m/s2 {20G} 200Hz up /down 4h, forward/back 2h, conforms to JIS D1601 standard |

| Shock resistance | 4.9×103 m/s2 {500G} 0.5ms up/down/forward/back 3 times each, conforms to JIS C5026 standard |

Theoretical cylinder thrust values at various operating pressures

| Bore size (mm) |

Cross-sec. area of cylinder (mm2) |

Rod dia. (mm) |

Cross-sec. area of piston rod (mm2) |

Area of piston's rod face (mm2) |

Cylinder thrust (kN) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7MPa | 14MPa | 21MPa | 25MPa | ||||||

| φ40 | 1256 | φ22.4 (B) φ28 (A) |

394 615 |

Push | 1256 | 8.79 | 17.59 | 26.38 | 31.41 |

| Pull | 862 640 |

6.03 4.48 |

12.07 8.97 |

18.11 13.45 |

21.56 16.02 |

||||

| φ50 | 1963 | φ22.4 (C) φ28 (B) φ36 (A) |

394 615 1017 |

Push | 1963 | 13.74 | 27.48 | 41.23 | 49.08 | Pull | 1569 1347 945 |

10.98 9.43 6.61 |

21.97 18.86 13.23 |

32.95 28.30 19.95 |

39.23 33.69 23.64 |

| φ63 | 3117 | φ28 (C) φ36 (B) φ45 (A) |

615 1017 1590 |

Push | 3117 | 21.82 | 43.64 | 65.46 | 77.93 |

| Pull | 2501 2099 1526 |

17.51 14.69 10.68 |

35.02 29.39 21.37 |

52.53 44.08 32.06 |

62.53 52.48 38.17 |

||||

| φ80 | 5026 | φ36 (C) φ45 (B) φ56 (A) |

1017 1590 2463 |

Push | 5026 | 35.18 | 70.37 | 105.55 | 125.66 |

| Pull | 4008 3436 2563 |

28.06 24.05 17.94 |

56.12 48.10 35.88 |

84.18 72.15 53.83 |

100.21 85.90 64.08 |

||||

| φ100 | 7853 | φ45 (C) φ56 (B) φ70 (A) |

1590 2463 3848 |

Push | 7853 | 54.97 | 109.95 | 164.93 | 196.34 |

| Pull | 6263 5390 4005 |

43.84 37.73 28.03 |

87.68 75.47 56.07 |

131.53 113.21 84.11 |

156.58 134.77 100.13 |

||||

| φ125 | 12271 | φ56 (C) φ70 (B) φ90 (A) |

2463 3848 6361 |

Push | 12271 | 85.90 | 171.80 | 257.70 | 306.79 |

| Pull | 9808 8423 5910 |

68.66 58.96 41.37 |

137.32 117.92 82.74 |

205.98 176.89 124.11 |

245.22 210.58 147.75 |

||||

| φ140 | 15393 | φ63 (C) φ80 (B) φ100 (A) |

3117 5026 7853 |

Push | 15393 | 107.75 | 215.51 | 323.23 | 384.84 |

| Pull | 12276 10367 7539 |

85.93 72.57 52.77 |

171.87 145.14 105.55 |

257.80 217.71 158.33 |

306.91 259.18 188.49 |

||||

| φ160 | 20106 | φ70 (C) φ90 (B) φ110 (A) |

3848 6361 9503 |

Push | 20106 | 140.74 | 281.48 | 422.23 | 502.65 |

| Pull | 16257 13744 10602 |

113.80 96.21 74.22 |

227.60 192.42 148.44 |

341.41 288.63 222.66 |

406.44 343.61 265.07 |

||||

| φ180 | 25446 | φ80 (C) φ100 (B) φ125 (A) |

5026 7853 12271 |

Push | 25446 | 178.12 | 356.25 | 534.38 | 636.17 |

| Pull | 20420 17592 13175 |

142.94 123.15 92.22 |

285.88 246.30 184.45 |

428.82 369.45 276.67 |

510.50 439.82 329.37 |

||||

| φ200 | 31415 | φ90 (C) φ100 (B) φ140 (A) |

6361 9503 15393 |

Push | 31415 | 219.91 | 439.82 | 659.73 | 785.39 |

| Pull | 25054 21912 16022 |

175.37 153.38 112.15 |

350.75 306.77 224.30 |

526.13 460.16 336.46 |

626.35 547.81 400.55 |

||||

| φ220 | 38013 | φ100 (C) φ125 (B) φ160 (A) |

7853 12271 20106 |

Push | 38013 | 266.09 | 532.18 | 798.27 | 950.33 |

| Pull | 30159 25741 17907 |

211.11 180.18 125.34 |

422.23 360.37 250.69 |

633.34 540.56 376.04 |

753.98 643.53 447.67 |

||||

| φ250 | 49087 | φ110 (C) φ140 (B) φ180 (A) |

9503 15393 25446 |

Push | 49087 | 343.61 | 687.22 | 1030.83 | 1227.18 |

| Pull | 39584 33693 23640 |

277.08 235.85 165.48 |

554.17 471.71 330.96 |

831.26 707.56 496.45 |

989.60 842.33 591.01 |

||||

Dimensions

Hydraulic Cylinder built-in inrodsebsor CYLNUC MarkII MILL type MIIM

Hydraulic Cylinder built-in inrodsebsor CYLNUC MarkII JIS type MIIJ

Ex.

| Item | Code | Description | |||||

|---|---|---|---|---|---|---|---|

| Operating fluid | F | Specify only if phosphate ester is required. | |||||

| Cylinder type | J | JIS type | |||||

| M | MILL(JHOS) type | ||||||

| Bore size (mm) | 63~160 | 63 | 80 | 100 | 125 | 140 | 160 *1 |

| Rod dia. (mm) | A | 45 | 56 | 70 | 90 | 100 | 110 |

| B | 36 | 45 | 56 | 70 | 80 | 90 | |

| C | - | 36 | 45 | 56 | 63 | 70 | |

| Stroke(mm) | 50~800 | Rod diameter: less than 50 | 50~500:50 units 600~1000:100 units 1200~1600:200 units |

||||

| 50~1600 | Rod diameter: 50 or more | ||||||

| Mounting style | [LA] | Foot/Side Lugs |

|||||

| [FA] | Flange on rod end side |

||||||

| [TA] | Trunnion on Rod End Side |

||||||

| [TC] | Intermediate Fixed Trunnion |

||||||

| Maximum operating pressure | 70 | 7 MPa(70kgf/cm2) | |||||

| 140 | 14 MPa(140kgf/cm2) | ||||||

| 210 | 21 MPa(210kgf/cm2) | ||||||

| 250 | 25 MPa(250kgf/cm2) ※Only rod diameter 50 or more | ||||||

| Cushion | B | Both ends of cylinder | |||||

| R | Pull | ||||||

| H | Push | ||||||

| N | None | ||||||

| Cushion valve location *2 | A |  |

|||||

| B | |||||||

| C | |||||||

| D | |||||||

| N | None | ||||||

| Option | E | Long rod end | |||||

| G | Bellows, neoprene 130℃ max. | ||||||

| H | Bellows, silicone glass 250℃ max. | ||||||

| (E) K *3 | Lock nut | ||||||

| L | Clevis / single | ||||||

| M | Clevis / double | ||||||

| Connector | B | NSD standard connector (NJW-2012-PM) | |||||

| P | Large type connector for KPEV-S cable (NWPC-4012-Ad12) | ||||||

| R | Crimp-type terminal (R1.25-4) | ||||||

| Z | No connector | ||||||

| Cable length | 5 | 5m | |||||

| 10 | 10m | ||||||

| 20 | 20m | ||||||

| Port location *2 Air-breede location Cable location |

A |  |

|||||

| B | |||||||

| C | |||||||

| D | |||||||

*1: MIIM only

*2: The port and the cushion valve cannot be mounted facing in the same location.

*3: If a lock nut (K) is to be mounted at the rod end, the "long rod end style" item (E) must be selected.

System Configuration

Specification

Cylinder

| 項目 | Specification | |

|---|---|---|

| Bore size (mm) | φ50 or more | φ80 or more |

| Rod dia. (mm) | φ36 or more | φ50 or more |

| Maximum stroke length(mm) | 800 | 1600 |

| Maximum operating pressure(MPa) | MIIJ:21 MIIM:25 | |

| Proof test pressure(MPa) | 31.5 | 37.5 |

| Operating fluid | Mineral oil, water-glycol, polyol ester, phosphate ester, water-in-oil emulsion |

|

| Cylinder speed range(mm/s) | 8〜500 | |

| Ambient operating temperature(℃) | 5〜120 | |

Applicable sensor

| Item | Specification | ||||||

|---|---|---|---|---|---|---|---|

| Converter model | IRS-51.2P18 | IRS-51.2P30 | |||||

| Absolute detection range(mm) | 51.2 | ||||||

| Resolution(μm) | 6.25 | ||||||

| Repeatability(μm) | 10 mim. [Without load] | ||||||

| Linearity error(mm) | 0.15 + L/5000 Max. L:stroke | ||||||

| Temperature drift | Head (mm/℃) | 0.003 | |||||

| Scale(mm/℃) | 17.3 × 10-6 | ||||||

| Protection rating | IP67(Conforms to JEM 1030 standard) | ||||||

| Stroke(mm) | 512 | 800 | 768 | 896 | 1152 | 1600 | |

| Vibration resistance | Thrust(m/S2) | 2.0×102 {20G} *1 | |||||

| Radial(m/S2) | 2.0×102 {20G} *1 | 6.9×10 {7G} *1 | 2.0×102 {20G} *1 | 1.5×102 {15G} *1 | 9.8×10 {10G} *1 | 2.9×10 {3G} *1 | |

| Shock resistance | Thrust(m/S2) | 4.9×103 {500G} *2 | |||||

| Radial(m/S2) | 9.8×102 {100G} *2 | 4.9×102 {50G} *2 | 7.8×102 {80G} *2 | 5.9×102 {60G} *2 | 3.9×102 {40G} *2 | 2.0×102 {20G} *2 | |

*1:200Hz, 4h (JIS D1601)

*2:0.5ms 3 times (JIS C5026)

Theoretical cylinder thrust values at various operating pressures

| Bore size (mm) |

Cross-sec. area of cylinder (mm2) |

Rod dia. (mm) |

Cross-sec. area of piston rod (mm2) |

Area of piston's rod face (mm2) |

Cylinder thrust (kN) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7MPa | 14MPa | 21MPa | 25MPa | ||||||

| φ63 | 3117 | φ36 (B) φ45 (A) |

1017 1590 |

Push | 3117 | 21.82 | 43.64 | 64.46 | 77.93 |

| Pull | 2099 1526 |

14.69 10.68 |

29.39 21.37 |

44.08 32.06 |

52.48 38.17 |

||||

| φ80 | 5026 | φ36 (C) φ45 (B) φ56 (A) |

1017 1590 2463 |

Push | 5026 | 35.18 | 70.37 | 105.55 | 125.66 |

| Pull | 4008 3436 2563 |

28.06 24.05 17.94 |

56.12 48.10 35.88 |

84.18 72.15 53.83 |

100.21 85.90 64.08 |

||||

| φ100 | 7853 | φ45 (C) φ56 (B) φ70 (A) |

1590 2463 3848 |

Push | 7853 | 54.97 | 109.95 | 164.93 | 196.34 |

| Pull | 6263 5390 4005 |

43.84 37.73 28.03 |

87.68 75.47 56.07 |

131.53 113.21 84.11 |

156.58 134.77 100.13 |

||||

| φ125 | 12271 | φ56 (C) φ70 (B) φ90 (A) |

2463 3848 6361 |

Push | 12271 | 85.90 | 171.80 | 257.70 | 306.79 |

| Pull | 9808 8423 5910 |

68.66 58.96 41.37 |

137.32 117.92 82.74 |

205.98 176.89 124.11 |

245.22 210.58 147.75 |

||||

| φ140 | 15393 | φ63 (C) φ80 (B) φ100 (A) |

3117 5026 7853 |

Push | 15393 | 107.75 | 215.51 | 323.26 | 384.84 |

| Pull | 12276 10367 7539 |

85.93 72.57 52.77 |

171.87 145.14 105.55 |

257.80 217.71 158.33 |

306.91 259.18 188.49 |

||||

| φ160 | 20106 | φ70 (C) φ90 (B) φ110 (A) |

3848 6361 9503 |

Push | 20106 | 140.74 | 281.48 | 422.23 | 502.65 |

| Pull | 16257 13744 10602 |

113.80 96.21 74.22 |

227.60 192.42 148.44 |

341.41 288.63 222.66 |

406.44 343.61 265.07 |

||||

Explore a Career at NSD

Explore a Career at NSD Global Network

Global Network