VR TENSION®

Description

VR TENSION is a tension meter that measures tension on various webs, fibers, and wires.

This product offers optimal sensors for various environments, such as heat-resistance, waterproof, explosion-proof, and chemical-resistance.

It achieves measurement in harsh environments where it was impossible even if you wanted to measure.

- Structure

- Installation / Usage Image

- ADVANTAGE

- System Configuration

- Model coding

- Specification

- Dimensions

- Specification Confirmation Sheet

- Application Introduction

- Explosion Proof Solution Introduction

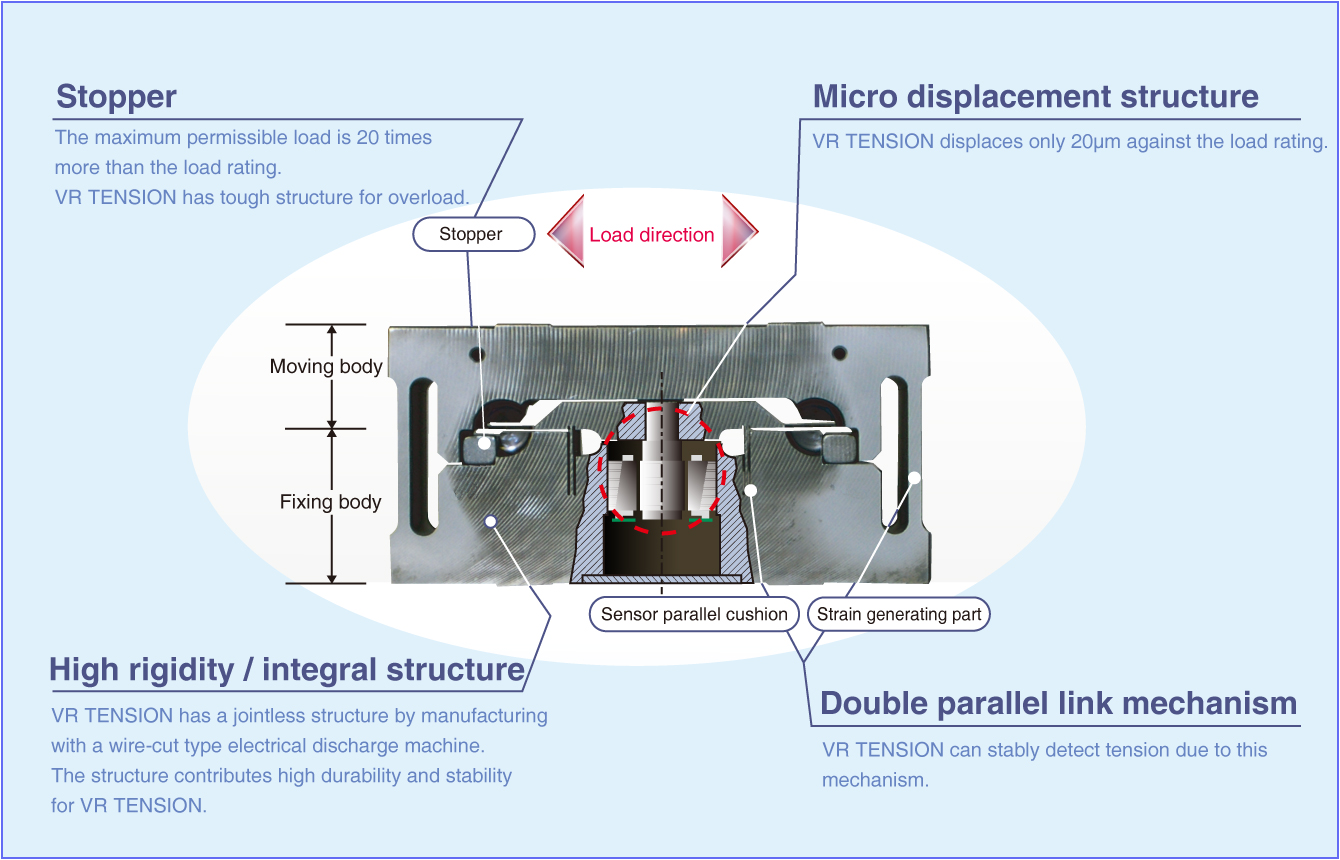

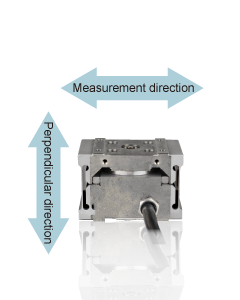

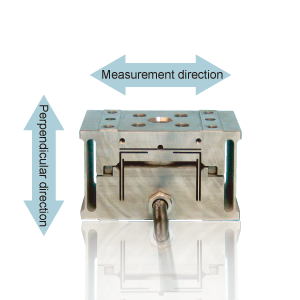

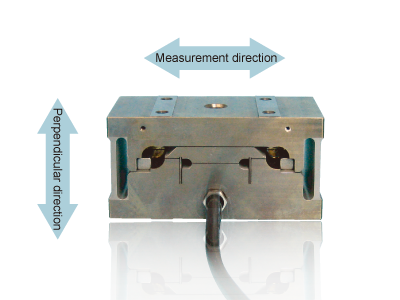

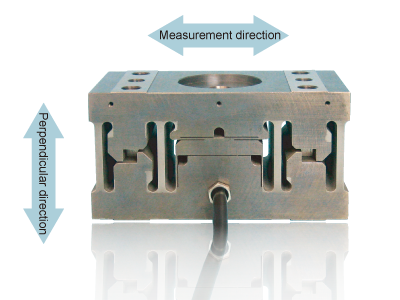

Structure

Installation / Usage Image

ADVANTAGE

No Zero Adjustment

Low to high tension measurement / Usable with cantilever roller

High response / Heat-resistance

Obtuse angle supported / Ultra-low tension detection

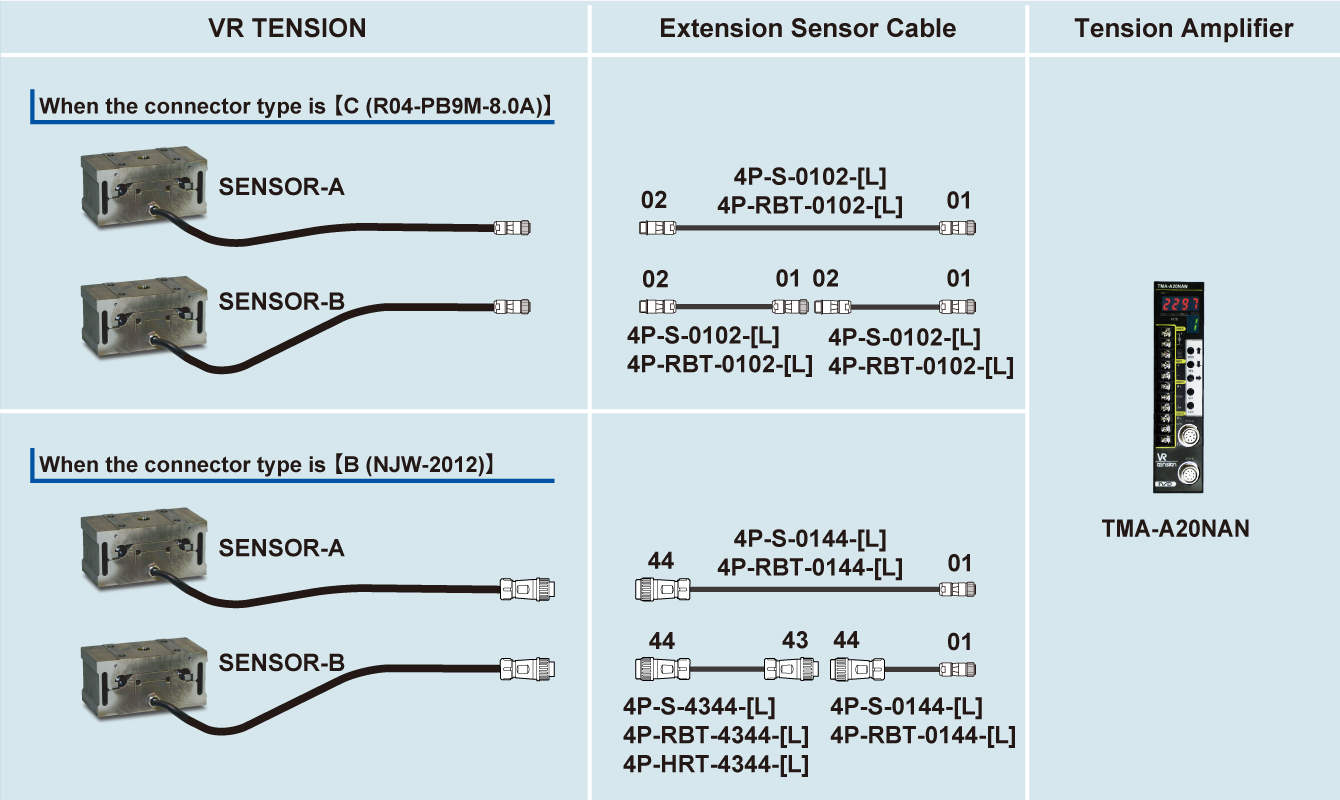

System Configuration

Please contact NSD for explosion-proof type.

Model coding

Sensor model

TMS - [1][2][3][4] - [Special specifications]

- [1] Load rating

-

Code Specification ST002 1.96N(0.2kgf) SS005 4.9N(0.5kgf) S02 19.6N(2kgf) S05 49N(5kgf) A10 98N(10kgf) A20 196N(20kgf) A50 490N(50kgf) B100 980N(100kgf) B200 1960N(200kgf) B300 2940N(300kgf) - [2] Sensor type

-

Code Specification Operating temperature ※1 Protection rating A Standard -10 ~ +60℃ IP40 B Heat-resistant -10 ~ +120℃ C Special with heat-resistant -10 ~ +150℃ L Standard -10 ~ +60℃ IP67 M Heat-resistant -10 ~ +120℃ N Special with heat-resistant -10 ~ +150℃ ※1 The ambient operating temperature of the connector is in the range between -25 and +85℃.

- [3] Connector type

-

Code Specification B Connecter NJW-2012 * when selecting the sensor type B, C, M, or N C Connecter R04-PB9M-8.0A * when selecting the sensor type A or L - [4] Interconnecting cable length

-

Code Specification Blank 2m (Standard) 5 5m 10 10m 20 20m - 0 to 10V voltage / 4 to 20mA current

- 2-CH output

Amplifier model

TMA-A20NAN

Specification

Sensor specification

| Item | Specification | ||||

|---|---|---|---|---|---|

| Sensor specification |

|

|

|

||

| Load rating | 1.96N 0.2kgf |

4.9N 0.5kgf |

19.6N 2kgf |

49N 5kgf |

|

| Accuracy | ±1% | ||||

| Rated load distortion | Approx. 0.02mm | ||||

| Repeatability | 0.2% | ||||

| Resolution | 0.12mN [0.012gf] |

0.3mN [0.03gf] |

1.19mN [0.12gf] |

2.99mN [0.30gf] |

|

| Interconnecting cable length | 2, 5, 10, 20m (Standard is 2m) | ||||

| Max. sensor cable length |

Standard | 100m * maximum total length of interconnecting cable and extension cable | |||

| Robotic | 100m * maximum total length of interconnecting cable and extension cable | ||||

※1 The ST/SS series has a smaller rating load, which limits the range of use compared to other series.

When using the sensor in a mounting direction except horizontal, pay attention to the mass of the sensor's main body moving parts and the mass of the tare weight.

※2 The ST/SS series is not designed with "Double parallel link mechanism".

When installing the sensor, be careful not to apply the sensor unbalanced load to the component.

| Item | Specification | ||||||

|---|---|---|---|---|---|---|---|

| Sensor specification |

|

|

|||||

| Load rating | 98N 10kgf |

196N 20kgf |

490N 50kgf |

980N 100kgf |

1960N 200kgf |

2940N 300kgf |

|

| Accuracy | ±1% | ||||||

| Rated load distortion | Approx. 0.02mm | ||||||

| Repeatability | 0.2% | ||||||

| Resolution | 5.98mN [0.61gf] |

11.96mN [1.22gf] |

29.9mN [3.05gf] |

59.8mN [6.10gf] |

119.6mN [12.2gf] |

179.4mN [18.3gf] |

|

| Interconnecting cable length | 2, 5, 10, 20m (Standard is 2m) | ||||||

| Max. sensor cable length |

Standard | 100m * maximum total length of interconnecting cable and extension cable | 100m | ||||

| Robotic | 100m * maximum total length of interconnecting cable and extension cable | 100m | |||||

Amplifier specification

| Item | Specification |

|---|---|

| Model | TMA-A20NAN |

| Voltage | 24VDC±10% (including ripple) |

| Power consumption | 10W or less |

| Mass | Approx. 0.4kg |

| Data display | 7-segment, 4-digit of LED + sign |

| Number of detection axes | 2 axes |

| Analog filter | 12Hz |

| Sampling interval | 0.2 to 20ms (The multiple numbers of 0.2ms is set by the parameter.) |

| Tension data display contents | A-axis, B-axis, A+B axes |

| External preset | None |

| Analog output specification | 0 to 10V voltage, 4 to 20mA current |

Explore a Career at NSD

Explore a Career at NSD Global Network

Global Network